The PaintPot manufacturing process is a new way to create low-cost, low-profile, highly customizable potentiometers for position sensing in robotic applications. It uses widely accessible materials, requires no special expertise, and creates custom potentiometers in a variety of shapes and sizes, including curved surfaces.PaintPots offer accuracy and precision performance comparable with commercial (non-customizable) options through a calibration process that trades small computation for cost.

The conference paper includes detailed PaintPot manufacturing and calibration processes, and experiments that validate the accuracy, precision, and lifetime performance of PaintPots, comparable to commercial sensors. We also provide a case-study application in the SMORES-EP modular robot, and show how the PaintPot process can be used to create resistive surfaces capable of sensing position in 2D on planes and spheres.

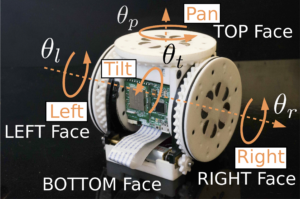

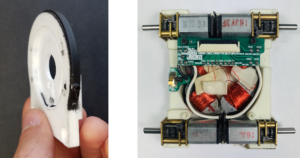

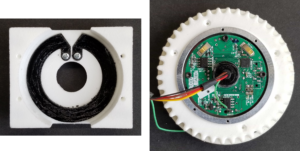

In the journal paper, we present a complete solution for the use of PaintPots in compact robotic systems with tight space constraints, and an example application in SMORES-EP. Two different designs of PaintPot sensors are used in SMORES-EP modular robots. In each SMORES-EP module, there are four degrees of freedom (DOFs) requiring position sensing — three continuously rotating joints (LEFT DOF, RIGHT DOF, PAN DOF) and one bending joint with a 180° range of motion (TILT DOF). These three continuously-rotating faces have Wheel PaintPots with circular tracks and wipers offset parallel to the axis of rotation, while the central hinge has a Tilt Paint Pot that covers 180° arc with a wiper offset normal to the axis of rotation.

A PaintPot is powered between ground and 3.3V. For wheel PaintPots, two wipers can contact the track and report measured voltage in the form of two 10bit analog-to-digital conversion values ranging from 0 to 1023. When a wiper contacts on or around the V-shape gap, the measurement is not usable. This is the reason for having two wipers, to enable sensing the full 360° range. For tilt PaintPots, a single wiper contacts the track all the time.

The manufacturing process is easy enough for a person to make a sensor quickly, but does not yield consistent measurement and performance. The terminal-to-terminal resistance can vary over a large range depending on the thickness of the paint with a non-linear output. An automatic sensor calibration setup is developed based on AprilTags tracking. Three tags are used to track the rigid bodies of a SMORES-EP module. During characterization, one DOF is moved at a time through its entire range of motion in both directions. The position information and reported voltage are recorded at 14Hz. For position estimation, we developed a Kalman filter with a simplified observation model to deal with the non-linearity (also piece-wise for wheel PaintPots due to the track gap) issues that result in the use of low-cost microcontrollers. For wheel PaintPots, we shift some segment of original observation model to generate a new continuous model. In order to avoid linearizing the nonlinear observation model, we change the measurement to be the reported position states rather than the original reported voltages. Given measured voltage, converted measurements can be derived easily. With this trick, a linear observation model is derived. This position estimation approach is validated on real hardware with very low error.

-

![[PDF]](https://www.modlabupenn.org/wp-content/plugins/papercite/img/pdf.png) T. Tosun, D. Edgar, C. Liu, Tsabedze Thulani, and M. Yim, “Paintpots: low cost, accurate, highly customizable potentiometers for position sensing,” in Ieee international conference on robotics and automation, 2017.

T. Tosun, D. Edgar, C. Liu, Tsabedze Thulani, and M. Yim, “Paintpots: low cost, accurate, highly customizable potentiometers for position sensing,” in Ieee international conference on robotics and automation, 2017.

[Bibtex]@InProceedings{TT:DE:CL:TT:MY:17, title = {PaintPots: Low Cost, Accurate, Highly Customizable Potentiometers for Position Sensing}, author = {Tosun, Tarik and Edgar, Daniel and Liu, Chao and Tsabedze, Thulani, and Yim, Mark}, booktitle = {IEEE International Conference on Robotics and Automation}, pdf={https://www.modlabupenn.org/wp-content/uploads/2017/10/tosun2017paintpots.pdf}, year = 2017 }

-

![[PDF]](https://www.modlabupenn.org/wp-content/plugins/papercite/img/pdf.png)

![[DOI]](https://www.modlabupenn.org/wp-content/plugins/papercite/img/external.png) C. Liu, T. Tosun, and M. Yim, “A low-cost, highly customizable solution for position estimation in modular robots,” Journal of mechanisms and robotics, 2021.

C. Liu, T. Tosun, and M. Yim, “A low-cost, highly customizable solution for position estimation in modular robots,” Journal of mechanisms and robotics, 2021.

[Bibtex]@article{CL:TT:MY:21, author = {Chao {Liu} and Tarik {Tosun} and Mark {Yim}}, title = {A Low-Cost, Highly Customizable Solution for Position Estimation in Modular Robots}, journal = {Journal of Mechanisms and Robotics}, year = 2021, doi = {10.1115/1.4050249}, pdf = {https://arxiv.org/abs/2201.03719} }

Pingback:ModLab UPenn » Archive » SMORES-EP

Pingback:Temporärbüro

Pingback:บริษัทรับสร้างบ้านเชียงใหม่

Pingback:fk brno 7.5

Pingback:Pretty Gaming

Pingback:นามบัตรด่วน

Pingback:massage bundoora

Pingback:จัดจำหน่าย บุหรี่ไฟฟ้า

Pingback:slot onlineค่ายเกมดังยอดฮิต 2023

Pingback:ร้านเค้กวันเกิดใกล้ฉัน

Pingback:genie168

Pingback:pk789

Pingback:เกมคาสิโนยอดนิยมที่ เกมไพ่ ให้เล่นครบทุกประเภทที่ W88

Pingback:ทางเข้าpg

Pingback:オンラインカジノ

Pingback:link

Pingback:ทำความรู้จักค่ายเกมส์ Evoplay

Pingback:เว็บ แทงมวย การเดิมพันเว็บแทงมวยตรงไม่ผ่านเอเย่นต์

Pingback:สล็อตเว็บตรง เปิดโหมดเกมฟรี

Pingback:Telegram中文

Pingback:หวย

Pingback:ผลิตเสื้อยืด

Pingback:Monsterxbet รับพนันกีฬา คาสิโนออนไลน์

Pingback:Доставка авто з США та Європи під ключ

Pingback:ดูบอลสด66

Pingback:สกรีนแก้ว

Pingback:โกดังเช่า ราคาถูก

Pingback:Databet

Pingback:ลำโพง TOA

Pingback:Weed

Pingback:pobieranie mostbet

Pingback:bgame777

Pingback:โคมไฟ

Pingback:Ricky Casino

Pingback:ร้านดอกไม้

Pingback:where to buy shrooms in california

Pingback:ซ่อม Fire Pump

Pingback:ตรวจสอบสลิปโอนเงิน

Pingback:girls outcall massage Bangkok

Pingback:Cbd edibles uk

Pingback:ระบบขายของออนไลน์

Pingback:บุหรี่นอก